Low speed(minimal noise)operation and compact design

3813-191 Kamiyamada, Chikuma-shi, Nagano-ken 389-0822, Japan

3813-191 Kamiyamada, Chikuma-shi, Nagano-ken 389-0822, Japan

Low speed(minimal noise)operation and compact design

Equipped with a compact geared motor (including a hypoid gear), the Compack's compact design allows for easy placement alongside the plastic molding machine.

It features a new, simple design that reflects Holon Seiko's revolutionary approach to industrial granulators.Because of this unique design, the Compack is able to conform well to any factory setting.

Easy, Thorough Cleaning

Covers of both sides of the granulator can be opened to facilitate full viewing of the rough crusher and granulator blades during detailed cleanings.

All old product residues can be completely removed before the addition of new materials.

Air Cleaning (optional) is available to clean the machin easily, as well as shorten the cleaning time without any release of debris outside the machine.

Complete Elimination of Cutting Errors

The Compack completely eliminates the possibility of cutting errors by passing the plastic runners through the rough crushing blades and the granulator blades only one time each.

Additionally, this machine features a screenless operation that prevents materials from getting jammed between the blades.

Long Life Expectancy

The Compack is composed of alloy steel parts which provide superior protection against abrasion.

Even when this granulator is used solely for the constant granulation of material containing glass fiber, the same reliable output can be expected long-term.

The granulator’s fixed blades feature for long life expectancy.

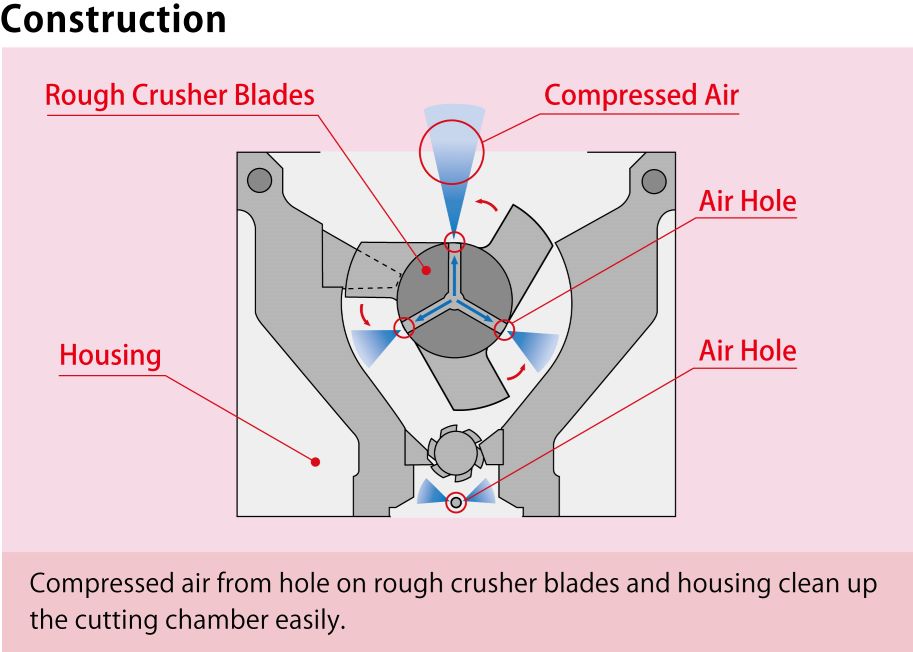

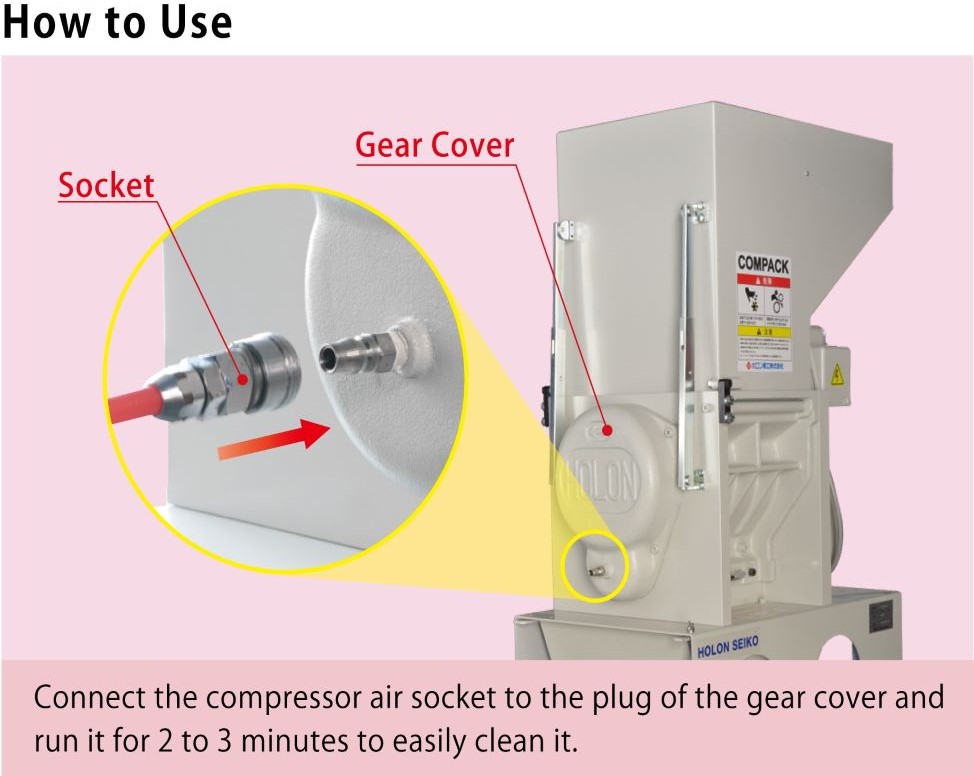

Air cleaning (option)

"Air Cleaning" function (option) has been added on COMPACK. Only by connecting to the compressed air, you can simply clean it. You can also reduce the time of cleaning without residual powder on the floor.

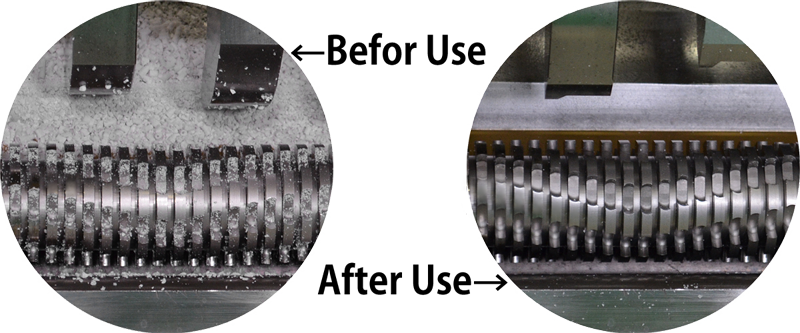

Comarative Test

※Smaller materials than usual were tested for comparison.

The Standard for Plastic Runner Granulator

We sold over 7,000 units of this machine in the world. As well as domestic customer, USA, China, Korea, Thailand, Vietnam, Indonesia, Philippines, etc. Many plastic molding plants are using the COMPACK series as repeat customers.

Specification

※You can scroll horizontally

| Model | Geared motor (KW) |

Crushing blade’s revolutions per minute 50/60Hz(rpm) |

Granulating blade’s revolutions per minute 50/60Hz(rpm) |

Granulating blade’s upper section size (mm) |

Material recovery tank’s capacity (L) |

Vacuum powered reception box’s capacity (L) |

Weight (Kg) |

Runner size (L mm)(D mm) |

|---|---|---|---|---|---|---|---|---|

| MC160-4 | 0.4 | 21/25 | 50/60 | 160×160 | 20 | 20 | 70 | ~140 ~7 |

| MC250-7 | 0.75 | 15/18 | 50/60 | 250×250 | 40 | 40 | 170 | ~203 ~9 |

| MC400-15 | 1.5 | 14/17 | 50/60 | 400×400 | 40 | 40 | 340 | ~380 ~12 |

※Electrical power cord measures 4.5 meters. All models require an adaptor with three-phase , which is not included.

※Specifications and design are subject to change without prior notification.

All of our machines feature a one year warranty effective from the date of installation.This warranty is limited to the replacement of parts. Holon Seikoassumes no liability for the products produced from these machines, for any difficulties encountered in the production process, or for any loss that may result from these problems.

It varies greatly depending on the use frequency; however, we have many records of the machines that have processed glass filler-free plastic for 10 years with no maintenance.

Check the length of the runner as a guide, which is shown in the model number after "MC". For details, see Runner size in COMPACK (specifications).

Opening both sides of the side cover, you can see rough crusher blades, granulator blades, and fixed blades clearly and you can clean them perfectly in a short time.