Patented crushing mechanism

3813-191 Kamiyamada, Chikuma-shi, Nagano-ken 389-0822, Japan

3813-191 Kamiyamada, Chikuma-shi, Nagano-ken 389-0822, Japan

SC・SH Series

Patented crushing mechanism

The unique crushing mechanism (shredder-type crushing blades) patented as No. 3173772. That mechanism completely eliminates the possibility of cutting errors.

Uniform Granulated Material

This machine features both shredder style and comb teeth blades to ensure uniform size and clean cut surfaces of the granulated material.

Compact Design

Due to its simple and compact design, the BITEX is space-saving and easy to move.

The best machine for the recycling of plastic containers and household electronics

The triaxial mill is suitable for recycling plastic containers up to about 600 mm in size, home appliances including non-ferrous metals, and defective plastic products.

SH Model Crusher

SH model is 2 axis crusher (this is idential to the SC model except for the fact that this is not equipped with the granulator blades.) This model can expell at 20 ~ 40 mm granulated aterial.

LSC, LSH Series

The best machine for the recycling of plastic containers and household electronics

LSC700 and LSH700 models with additional biting edges can easily grasp larger recycled material up to approximately 500 mm in diameter, which exceeds the capacity of the SC700 model

SR Series

Low Price

We have reduced the number of parts to the minimum to achieve the price reduction comparing conventional SH series. That is based on patent No. 3173772, as same as SC and SH series.

Compact Design

The simple design has made it more compact than SH series.

The BITEX series has sold more than 500 units in the world. Many molding plants and waste treatment plants are using the BITEX series as repeat customers.

※You can scroll horizontally

| Model | Geared motor (KW) |

Crushing blade’s revolutions per minute (rpm) 50/60Hz |

Granulating blade’s revolutions per minute (rpm) 50/60Hz |

Crushing blade’s size (mm) |

Granulating blade’s size (mm) W×H (optional accessory) |

Weight (Kg) |

|---|---|---|---|---|---|---|

| SC250-22 | 2.2 | 18/22 | 50/60 | 30 | 10×8 (6×7) | 350 |

| SC500-55 | 5.5 | 32/39 | 70/85 | 30 | 10×8 (6×7 15×12) | 550 |

| SC500-110 | 11 | 53/64 | 116/140 | 30 | 10×8 (6×7 15×12) | 580 |

| SC700-150 | 15 | 53/64 | 125/150 | 44 | 10×9 (6×7 16×12) | 1260 |

| LSC700-150 | 15 | 53/64 | 125/150 | 44 | 10×9 (6×7 16×12) | 1360 |

| SR180-15 | 1.5 | 30/36 | - | 30 | - | 150 |

| SR380-37 | 3.7 | 28/33 | - | 30 | - | 400 |

| SH250-22 | 2.2 | 18/22 | - | 30 | - | 335 |

| SH500-55 | 5.5 | 32/39 | - | 30 | - | 530 |

| SH500-110 | 11 | 53/64 | - | 30 | - | 560 |

| SH700-150 | 15 | 53/64 | - | 44 | - | 1200 |

| LSH700-150 | 1.5 | 53/64 | - | 44 | - | 1300 |

※The numbers above are indications for thich plastics.

※Processing ability to PET plastic bottles is 0.7 times as much as the numbers above.

※We can produce a sample. Please send materials about 1 kg. The size of the sample approximates the size of the blade.

・We can test processing ability. Please send materials about 4 kg.

※Electrical power cord measures 4.5 meters. All models require an adaptor with three-phase , which is not included.

All of our machines feature a one year warranty effective from the date of installation.This warranty is limited to the replacement of parts. Holon Seiko assumes no liability for the products produced from these machines, for any difficulties encountered in the production process, or for any loss that may result from these problems.

Granulator (SC/LSC)

※You can scroll horizontally

| SC250-22 | SC500-55 | SC500-110 | SC700-150 | LSC700-150 | |

|---|---|---|---|---|---|

| Geared Motor (three-phase) |

2.2kW | 5.5kW | 11kW | 15kW | 15kW |

| Crushing Blade's Revolution per Minutes 50/60Hz(rpm) |

18/22 | 32/39 | 53/64 | 53/64 | 53/64 |

| Granulating Blade's Revolution per Minutes 50/60Hz(rpm) |

50/60 | 70/85 | 116/140 | 125/150 | 125/150 |

| Granulating Blade's Size | 10×8 | 10×8 | 10×8 | 12×9 | 12×9 |

| (6×7) | (6×7,15×12) | (6×7,15×12) | (6×7,16×12) | (6×7,16×12) | |

| Weight (kg) | 350 | 770 | 800 | 1540 | 1740 |

Crusher (SH/LSH)

※You can scroll horizontally

| SH250-22 | SH500-55 | SH500-110 | SH700-150 | LSH700-150 | |

|---|---|---|---|---|---|

| Geared Motor (three-phase) |

2.2kW | 5.5kW | 11kW | 15kW | 15kW |

| Crushing Blade's Revolution per Minutes 50/60Hz(rpm) |

18/22 | 32/39 | 53/64 | 53/64 | 53/64 |

| Granulating Blade's Revolution per Minutes 50/60Hz(rpm) |

- | - | - | - | - |

| Granulating Blade's Size | - | - | - | - | - |

| Weight (kg) | 335 | 740 | 770 | 1470 | 1670 |

Crusher (SR)

※You can scroll horizontally

| SR180 | SR380 | - | - | - | |

|---|---|---|---|---|---|

| Geared Motor (three-phase) (3-phase 200V) |

1.5kW | 3.7kW | - | - | - |

| Crushing Blade's Revolution per Minutes 50/60Hz(rpm) |

30/36 | 28/33 | - | - | - |

| Granulating Blade's Revolution per Minutes 50/60Hz(rpm) |

- | - | - | - | - |

| Granulating Blade's Size | - | - | - | - | - |

| Weight (kg) | 150 | 400 | - | - | - |

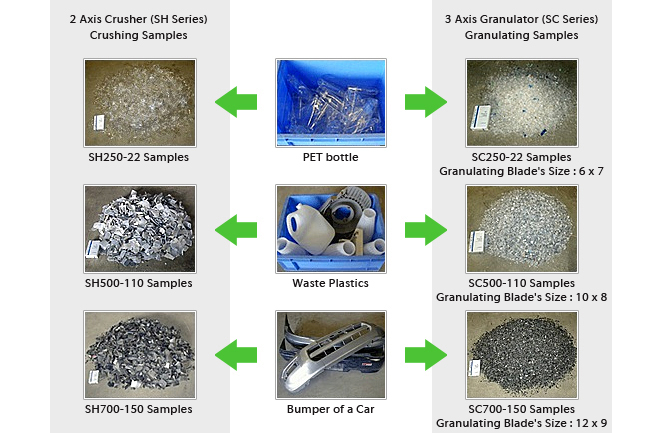

The biaxial crushing machine (SH series), not equipped with granulator, reduces volume. It produces crushed materials of 20 to 40mm cubes.

The triaxial granulator (SC series) is equipped with a biaxial crushing machine with granulator blades. It produces grain of about 6mm cubes minimum.

The model number of our granulators after SC or SH indicates the slot size. You can select a model roughly based on the size of materials to be granulated or crushed.

The basic mechanism is the same, however, SR series is simple and low-cost due to its design with less parts than SH series.