CP200-4 Grinding Image

3813-191 Kamiyamada, Chikuma-shi, Nagano-ken 389-0822, Japan

3813-191 Kamiyamada, Chikuma-shi, Nagano-ken 389-0822, Japan

evolution

"e・PELLETER" has evoluted as "EP50-16". The new machine has 16 nozzles and makes more production with same size of machine. This machine has a pellet feeding unit to raw material bags as a optional.

Air-cooling Type Pellet Production Machine (for stand-alone use)

The use of a special super short screw of our own design and an air-cooling system (patented) has minimized the deterioration of resin quality due to heating. The air-cooling system makes it possible to produce recycled pellets that do not require pre-drying before molding.

This machine’s simple design makes its price reasonable.Its compact design allows for placement alongside the molding machine as one machine “CUTandPELLETER” that is integrated with the granulator (COMPACK).

The melted strands are automatically fed into the cutter without manual feeding.You can operate this machine only by setting the speed of a screw and a cutter, heater temperature, and air flow, as well as setting the condition easily.

Air-cooling Type Pellet Production Machine (for production line (in-line) use)

Now e・Pelleter equips a granulating cutter inside.

After loading of runners expelled from the moldig machine, runners get granulated by the cutters and melted with the screw to form recycled pellets.

This system allows an instant pelletization of fixed runners following the molding cycles.

This machine is only applicable to runners discharged from the molding machine in a fixed cycle.

This compct design allows easy installation alongside your molding machine.

We propose replacement of the existing granulator by this machie.

Also it can be linked to a hopper loader when the vacuum collector device (optional accessory) attached.

cost saving

We simplified the granulating machanism and reduced the numbers of parts significantly.

Around 40% cost reduction than previous model has been achived.

CP200-4 Grinding Image

Pellet Production Machine with Blender

New machine with fixed quantity mixing arrived.

Fixed quantity mixing equipment installed CPB200-4 has been newly developed.

This can perform operations from granulating to pelletization and mixing by only this one machine.

It mixes recycled pellet and virgin materials at a certain fixed rate.

All an operator has to do is to load the materials. This machine will do the rest of works automatically.

This machine is only applicable to runners discharged from the molding machine in a fixed cycle.

Super short screw that minimizes quality degradation due to heating

Resin deterioration due to heating is unavoidable. We have succeeded in suppressing resin deterioration by using the super short screw designed and manufactured in-house.

Air cooling system as maintenance free

The melted strands from the extruder are efficiently cooled as they pass through the cooling pipe. There is no need to manage the cooling water or maintain the tank as in the case of the water cooling type. The air cooling system can produce recycled pellets that no need pre-drying before molding.

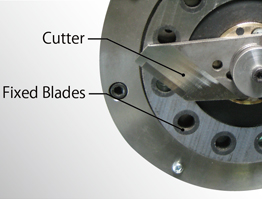

Superior Sharp Cutting

The cutter and fixed blades of the pelletizer are composed of cemented carbide which keeps the cutter life long even when cutting materials containing glass.

A unique gapless structure also produces uniformly-sized and good pellets even from soft elastomer.

The cold cut type makes almost no powder .

Compact design

The e-PELLETER is more compact than other companies' air-cooled granulators and can be used for repelletizing in a limited space. The c-PELLETER is almost as small as the e-PELLETER while incorporating the grinding mechanism, so it can be installed next to the molding machine without difficulty.

Pellet Sample

"e・PELLETER" and "c・PELLETER" make many kind of resin pellets, also colloring pellets with master batch.

Three types of nozzles

We have newly developed EP50-16 with 16 nozzles against EP50-4 with 4 nozzles and EP50-8 with 8 nozzles (Conventional machine).

It allows for high-volume production with material which takes time to cool down.

Automatic Shutdown

Turning the automatic shutdown switch ON, the main switch automatically turns OFF when materials end.

This function is safe for unattended operation at night.

Some Kinds of Screw (optional)

You can choose screw type, long type for super engineering plastic like a LCP, mixing type for coloring, etc.

Case1

Before Installation: When 600 kg runners of PA66 are wasted every month at ¥30/kg

【Loss】

Disposal cost:600 kg ×¥50=¥30,000

After Installation: When the same amount of runners as above are recycled to pellets by EP50-4

【Cost】

Payroll cost / ¥

¥3,000 / hour × 200 hours (※1) × 0.5 hours (※2) ÷ 10 hours (※2)

※1 Production time of EP50-4: 600 kg ÷ 3 kg/h =200 hours

※2 When EP50-4 operates 0.5 hours per 10 hours

Electricity cost / ¥

1.5 kw × ¥25 × 200 hours

Total cost / ¥

【Added value】

Recycled pellet price / ¥

600 kg × ¥1000/kg (※3)

※3 When raw material is ¥600/kg

・¥600,000 worth of recycled materials are produced from the residues that cost ¥18,000 for disposal every month.

・Approximately ¥7,100,000 can be gained per year by recycling old product residues.

¥10,000,000

Case2

Before Installation: When 1,200 kg granulating materials of PPS are processed by a subcontract factory every month at ¥200/kg

【Cost】

Subcontracting cost: 1,200 kg × ¥300/kg=¥360,000

After Installation: When the same amount of material as above is processed by in-house EP50-8

【Cost】

Payroll cost / ¥

¥3,000 / h × 200 hours (※4) × 0.5 hours (※5) ÷ 10 hours (※5)

※4 Production time of EP50-8 : 1,200 kg ÷ 6kg/h = 200 hours

※5 When EP50-8 operates 0.5 hours per 10 hours

Electricity cost / ¥

Total cost / ¥

・This case saves approximately ¥320,000 every monthもの¥3,840,000 every year.

・Controlling of the entire operations as processing, shipping, and storing in the company improves quality control.

¥500,000 / month

Strength Test Results of Recycled Pellets

We sold over 200 units of this machine in the world. As well as domestic customer, China, Korea, Thailand, Vietnam, Indonesia, Philippines, etc.

Specifications

※You can scroll horizontally

| Air-cooling Type Pellet Production Machine (for stand-alone use) |

Air-cooling Type Pellet Production Machine with Cutter (for production line (in-line) use) |

|||||

|---|---|---|---|---|---|---|

| - | - | With fixed quantity mixing | ||||

| EP50-4 | EP50-8 | EP50-16 | CP200-4 | CPB200-4 | ||

| Power | Three-Phase AC 200V (50/60Hz) | Three-Phase AC 200V (50/60Hz) | ||||

| Motor Capacity (kW) |

0.5(Standard) 0.85(Long Screw) |

0.5 | 1.0 | 0.5 | 0.6 | |

| Heater Capacity (kW) |

3.8(Standard) 5.0(Long Screw) |

3.9 | 5.5 | 3.8 | ||

| NOZZLE ID (mm) |

φ2,φ2.5(Standard),φ3 | φ2,φ2.5(Standard),φ3 | ||||

| Number of Nozzle | 4 | 8 | 16 | 4 | ||

| Length of Pellet (mm) |

~5 | ~5 | ||||

| Air Consumption (L/min) |

~100 (Required 1.5kW compressor) |

~150 (Required 1.5kW compressor) |

~100 (Required 1.5kW compressor) |

|||

| Weight (kg) |

150 | 180 | 170 | 200 | ||

| Runner Size L, D (L・Dmm) |

- | ~160, ~6 | ||||

Standard Features

※You can scroll horizontally

| Function | Note | |

|---|---|---|

| Indicator Lamp | Light and buzzer notify abnormalities occurred. | |

| Automatic Power Shut Off Function | When materials emptied, the main power will turn off automatically. | |

| Cutter (Spare Part) | One set of cutter for the pelletizer included as a spare. | |

| Cooling Pipe (Spare Part) | Cooling pipe includedas a apare. |

Optional Features

※You can scroll horizontally

| Function | Note | |

|---|---|---|

| Vacuum Collector Device | A box which can be connected to the hopper loader. | CPB200-4,EP50-16 includes this as a standard. |

| Collector-full Alarm | When pellet collector full, this will turn the alarm on. | |

| Long Screw | For super engineering plastics. | |

| Material Supply Device | For super engineering plastics. | |

| Coloring Screw | For dry color and master batch. | |

| Transport Device | Automatically transports produced pellets to material bags. | |

| Bridge Prevention System | For materials including elastomer that are prone to bridge in the hopper. |

※Model EP and CP are required compressed air.

※Electrical power cord measures 4.5 meters. All models require an adaptor with three-phase, which is not included.

※Specifications and design are subject to change without prior notification.

※All of our machines feature a one year warranty effective from the date of installation.This warranty is limited to the replacement of parts. Holon Seiko assumes no liability for the products produced from these machines, for any difficulties encountered in the production process, or for any loss that may result from these problems.

e・PELLETER and c・PELLETER respond to various resins. But, there are several difficult resin to product pellets. So, we conduct sample test, facing an inquiry.

Usually, 5 kg is enough. If you request c・PELLETER (for production line use), please send us plastic runners.

You can choose the nozzle diameter to decide a pellet O.D. The length of pellet can be adjusted by changing the revolving speed of a cutter.